Before we had any PAT tools, the process was like a black box to us. We put something in and get something out without knowing what happened inside. Now, we have an ‘Eye’ to look inside that black box and see what’s going on in there.

Get live data throughout your process and see what improves product quality in real-time. Gain insight from data-driven feedback control with greater product consistency and fewer batch reworks and rejects.

Monitor the evolution of your product processing with Multieye2. Evaluate your critical quality attributes continuously. Respond on time to deviations to improve batch quality while reducing the burden of time and cost on laboratory analysis.

Use Multieye2 to monitor your process remotely. Automatically adjust process parameters using sensor data in real-time to accelerate development and move to the next industrial revolution.

Capture the impact of your critical process parameters in real-time and gain control of your critical quality attributes. Track moisture content, API concentration, or density pre and post-transfer and simply demonstrate the equivalence of product scale-up.

| Spectral Range | 1050 – 2100 nm |

| Number of channels | Single Channel Unit Four Channel Unit (1-4) |

| Spectral resolution | 6 nm FWHM |

| Data acquisition time | From 1 ms, configurable and sample/processdependent, typically 100-150 ms |

| Spectrometer type | Transmissions diffraction grating with TE-cooled InGaAs CCD array detector |

| Dynamic range | 6000:1 |

| S/N | 2500:1 |

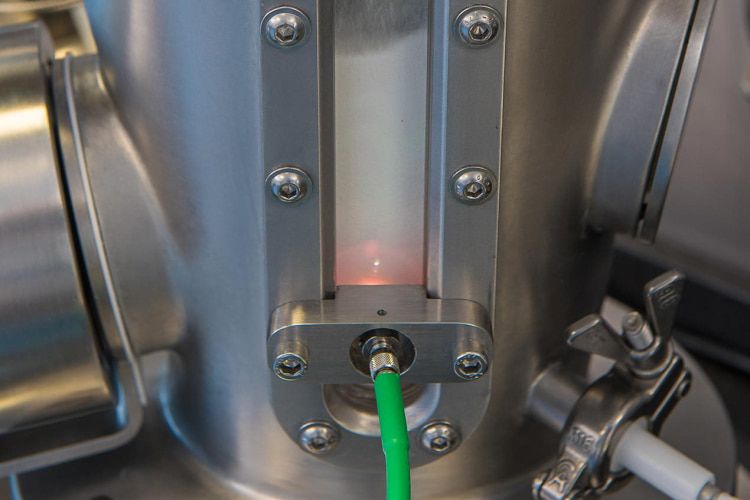

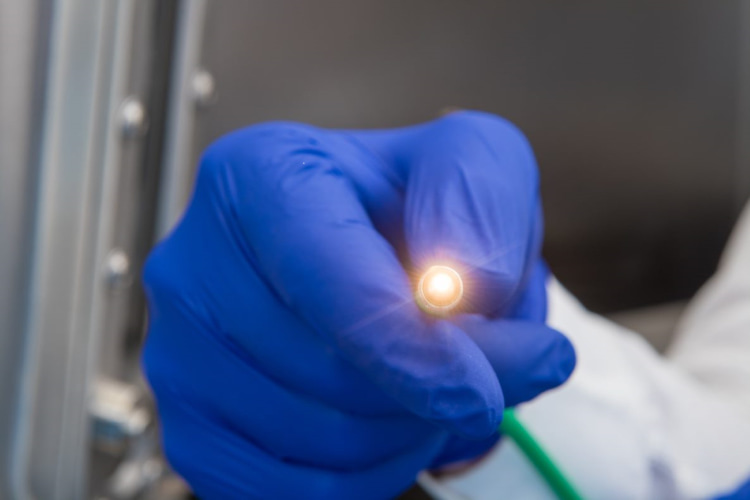

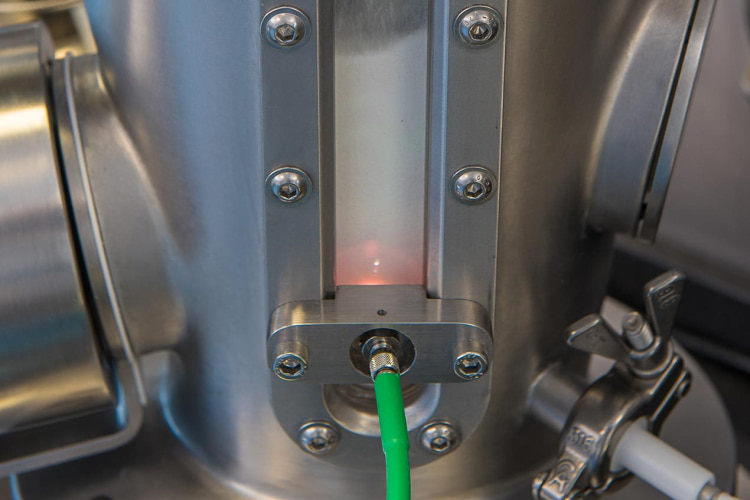

| Probes | Non-product contact as default, contact options also available |

| Spot Size | Configurable based on probe selection |

| Probe connectors | SC or SMA |

| Communications | Plug & Play USB OPC Support |

| Dimensions | (h) 95 x (w) 385 x (d) 245 mm |

| Power | 110VAC @ 50HZ / 230 VAC @ 50HZ |

| Weight | Approximately 9 kg |

With InnoGlobal Technology’s team of mechanical, electronic, and application engineers, we have extensive experience collaborating with process experts to achieve successful measurement and process integration solutions from the equipment level with Multieye2, to integration with automated software platforms, such as SmartX, for advanced process control.

For peace of mind, we invite customers to undertake a trial of their material at our Ireland application lab (with optional customer attendance), where we offer sample analysis with Multieye2. Trials can also replicate real-world conditions with a wide range of processing equipment available to offer assurance that Multieye2 can meet their analytical requirements

We at InnoGlobal Technology work with industry scientists and engineers to understand the challenges they face, and the risks when embedding new technology. Embedding NIR technology into your process provides a competitive edge, and InnoGlobal Technology aims to help facilities get to market faster, improve process understanding and achieve higher standards of quality by offering versatile solutions suited to their needs.

We help customers unlock the full potential of Multieye2 by offering a number of services. On-site training ensures users are confident with the technology, while top-notch customer support and extended maintenance contracts ensure you’re never more than a phone call away from help when needed. Chemometric model development offers an efficient and traceable method for system calibration/verification, and our IQ OQ template streamlines the qualification process, with optional on-site execution by our own expert engineers.